Using hot holding equipment to reheat food is not recommended due to potential food safety risks. Reheating food in hot holding equipment can lead to uneven heating, allowing harmful bacteria to grow and increasing the risk of foodborne illnesses.

Table of Contents

ToggleIt is important to prioritize proper reheating methods, such as using equipment designed for reheating or reheating food to the correct internal temperature. By following safe practices, you can minimize the risk of foodborne illnesses and ensure the safety of the food you serve.

What Is Hot Holding Equipment?

Hot holding equipment is used to keep food warm and ready for consumption. It can be convenient for reheating meals quickly and maintaining their temperature.

Hot holding equipment is a crucial component of the food service industry, allowing establishments to maintain the quality and safety of their food during service. In this section, we will explore the definition and purpose of hot holding equipment, as well as an overview of the different types available.

Definition And Purpose Of Hot Holding Equipment:

Hot holding equipment refers to appliances or tools designed to keep food at a specific temperature, typically above 140°F (60°C), until it is ready to be served. The primary purpose of hot holding equipment is to maintain the optimal temperature of cooked food, preventing it from entering the “danger zone” where bacteria can multiply rapidly.

Hot holding equipment is particularly useful for restaurants, cafes, and other food establishments where precooked food needs to be kept warm for extended periods.

By maintaining a steady temperature, hot holding equipment ensures that food remains safe, while also preserving its flavor, moisture, and texture.

Different Types Of Hot Holding Equipment:

There are several types of hot holding equipment available, each designed to accommodate different quantities and types of food.

Here are some common examples:

- Hot holding cabinets: These cabinets feature controlled heating elements and adjustable temperature settings. They are ideal for holding large quantities of food, such as trays of cooked meat, soups, or side dishes. The cabinets may have compartments with separate temperature controls, allowing for varied holding temperatures.

- Bain-maries: Also known as water baths, bain-maries consist of large pans or containers filled with hot water. Food is placed in smaller containers within the water bath, ensuring even heat distribution and preventing direct contact with the heating source. This method is commonly used for delicate items like sauces, custards, and puddings.

- Warming trays: Warming trays are convenient for smaller quantities of food or individual servings that need to be kept warm. These trays use a combination of direct heat and insulation to maintain the desired temperature. They are often used for appetizers, finger foods, or small dishes during catering events or buffet-style service.

- Heated shelves: These shelves are equipped with heating elements underneath, creating a warm surface to hold plates or food containers. Heated shelves are commonly seen in buffet setups, food displays, or cafeteria lines to keep food warm before it is served.

- Heat lamps: Heat lamps emit infrared heat, which helps keep food warm without drying it out. They are often used in conjunction with other hot holding equipment or at serving areas to ensure that food maintains its temperature while waiting to be served.

Hot holding equipment plays a vital role in maintaining food safety and quality in the food service industry. By understanding the various types available, establishments can choose the appropriate equipment to suit their specific needs and ensure a satisfying dining experience for their customers.

How Does Hot Holding Equipment Work?

Hot holding equipment is a reliable way to reheat food, ensuring it stays at a safe and proper temperature. By using this equipment, you can maintain the quality and freshness of your food while efficiently serving your customers.

Hot holding equipment is designed to maintain food at safe temperatures, ensuring that it stays warm and ready to serve. This equipment plays a crucial role in food service establishments, such as restaurants, cafeterias, and catering companies. Understanding how hot-holding equipment works can help you determine whether it is the right choice for reheating food in your kitchen.

The Temperature Control Mechanism:

Hot holding equipment utilizes a temperature control mechanism to maintain the necessary heat for food safety.

Here’s how it works:

- Thermostats: Most hot holding equipment is equipped with built-in thermostats that allow you to set and control the desired temperature. These thermostats ensure that the food remains within the safe temperature range, usually between 135°F (57°C) and 165°F (74°C), to prevent bacteria growth.

- Heating element: The heating element in hot holding equipment is responsible for generating heat and maintaining the desired temperature. It can be an electric element or a steam-pipe system, depending on the type of equipment.

- Insulation: Hot holding equipment is designed with proper insulation to minimize heat loss. This helps to maintain a consistent temperature throughout the unit and prevents the food from cooling down too quickly.

- Air circulation: Some hot-holding equipment, like convection ovens or holding cabinets, use fans to ensure even heat distribution. The circulating air helps to maintain a consistent temperature and prevents cold spots in the food.

Maintaining Food At Safe Temperatures:

Hot holding equipment effectively keeps food at safe temperatures, which is crucial for preventing foodborne illnesses and ensuring food quality.

Here’s how it achieves this:

- Heat retention: The insulation in hot holding equipment keeps the heat trapped inside, minimizing heat transfer to the outside environment. This allows the food to remain at a safe temperature for an extended period.

- Temperature monitoring: The built-in thermostats continuously monitor the temperature inside the equipment. If the temperature drops below the set range, the heating element automatically activates to bring it back to the desired level, ensuring food safety.

- Time limits: While hot-holding equipment can maintain safe temperatures, it is important to adhere to time limits. Holding food for too long can affect its quality and increase the risk of bacterial growth. Regularly monitoring the time and rotating the food can help maintain freshness and safety.

Hot holding equipment utilizes a temperature control mechanism, including thermostats, heating elements, insulation, and air circulation, to maintain food at safe temperatures. It plays a vital role in the food service industry, ensuring that food remains warm and ready to serve while minimizing the risk of foodborne illnesses.

Benefits Of Using Hot Holding Equipment

Hot holding equipment offers numerous benefits for reheating food. It helps to maintain the temperature of the food, ensuring it stays hot and ready to serve. This equipment also helps to preserve the quality and flavor of the food, making it a great option for commercial kitchens and food service establishments.

Hot holding equipment refers to specialized devices designed to keep food at a specific temperature until it is ready to be served. These equipment are widely used in the food industry, from restaurants to catering services, as they offer several benefits.

In this blog post, we will explore the advantages of using hot-holding equipment to reheat food. As you will see, these benefits include extending the shelf life of food, reducing food waste, and ensuring food safety and quality.

Extending The Shelf Life Of Food:

Hot-holding equipment helps extend the shelf life of prepared food by maintaining it at the appropriate serving temperature.

By preventing the food from cooling down and allowing harmful bacteria to grow, hot-holding equipment ensures that the food remains safe for longer periods.

With extended shelf life, businesses can reduce waste and save money by avoiding the need to discard food that has spoiled.

Reducing Food Waste:

Hot holding equipment allows businesses to store and hold food at the perfect serving temperature, minimizing the likelihood of food going to waste.

Instead of preparing and serving large quantities of food all at once, which can lead to excess and wastage, hot holding equipment enables businesses to prepare smaller batches and keep them warm until needed.

By reducing food waste, businesses can not only save money but also contribute to minimizing the environmental impact of food production and disposal.

Ensuring Food Safety And Quality:

Hot-holding equipment plays a crucial role in maintaining the safety and quality of food during the reheating process.

By keeping food at the appropriate temperature, hot holding equipment helps kill or inhibit the growth of harmful bacteria, ensuring that the food is safe to consume.

Additionally, hot holding equipment helps retain the flavor, texture, and nutritional value of the food, ensuring a pleasant dining experience for customers.

Using hot holding equipment to reheat food offers several benefits. It extends the shelf life of food, reduces food waste, and ensures food safety and quality. By investing in hot holding equipment, businesses can not only save money but also enhance their operational efficiency and customer satisfaction.

So, if you’re in the food industry, consider incorporating hot-holding equipment into your operations for a more efficient and sustainable approach to reheating food.

Food Safety Regulations And Guidelines

Using hot-holding equipment to reheat food can be a contentious issue under food safety regulations and guidelines. Ensure you thoroughly understand and comply with the regulations to maintain the safety and quality of your food.

Hot holding equipment is commonly used in the food service industry to quickly and efficiently reheat the food. However, before utilizing such equipment, it is crucial to understand and comply with the food safety regulations and guidelines.

Here is an overview of industry standards and the importance of adhering to local health codes:

Overview Of Industry Standards

- Temperature regulations: Hot holding equipment must meet specific temperature requirements to ensure food safety. The industry standard for hot holding equipment is to maintain a minimum internal temperature of 140°F (60°C) or higher to inhibit bacterial growth and maintain food quality.

- Temperature monitoring: Regular monitoring of food temperatures in hot holding equipment is essential. This can be done using calibrated food thermometers to verify that the internal temperature of the food remains within the safe range.

- Time limits: While hot-holding equipment can keep food warm for extended periods, it is important to follow specific time limits for holding and reheating food. The general industry guideline is to ensure that food does not spend more than two hours in the temperature danger zone (between 41°F and 140°F or 5°C and 60°C) to minimize the risk of bacterial growth.

- Storage practices: Proper storage practices play a vital role in maintaining food safety. Food items should be stored in covered containers to prevent cross-contamination and stored in specific zones in the hot holding equipment to ensure even heating.

Compliance With Local Health Codes And Regulations

- Local regulations: Each locality has its own health codes and regulations that food establishments must adhere to. These regulations ensure that food is handled, stored, and reheated safely. It is essential to familiarize yourself with the specific regulations in your area and ensure compliance to avoid potential penalties or health risks.

- Inspections: Health departments regularly inspect food establishments to ensure compliance with local regulations. During inspections, the proper use and maintenance of hot holding equipment may be evaluated. By adhering to the regulations, businesses can pass inspections and maintain their reputation for food safety.

- Training and certifications: Proper training and certifications are necessary to ensure that staff members are knowledgeable about food safety practices, including the use of hot-holding equipment. Certifications such as ServSafe provide valuable education and guidance in handling and reheating food safely.

- Documentation and record-keeping: Keeping records of food temperatures, equipment maintenance, and employee training is crucial for compliance purposes. These records not only demonstrate compliance with regulations but also help identify any potential issues and allow for timely corrective actions.

Hot-holding equipment can be a convenient method for reheating food, but it must be used in accordance with food safety regulations and guidelines. By following industry standards, complying with local health codes, and implementing proper training and record-keeping practices, food establishments can ensure the safe and efficient use of hot-holding equipment.

Types Of Food Suitable For Hot Holding

Hot holding equipment is an effective way to reheat food, ensuring it stays at a safe temperature. Various types of food, such as soups, stews, and sauces, are suitable for hot holding to maintain their quality and taste.

Foods That Are Safe And Maintain Quality When Reheated

Some foods are suitable for reheating using hot holding equipment as they maintain their safety and quality.

These foods include:

- Soups and stews: These liquid-based dishes can be safely reheated in hot holding equipment, ensuring that they reach the proper temperature for consumption.

- Cooked grains: Rice, quinoa, and other cooked grains can be reheated using hot-holding equipment to maintain their texture and flavor.

- Roasted or grilled meats: Meats that have been cooked through roasting or grilling can be safely reheated in hot holding equipment, preserving their tenderness and taste.

- Cooked vegetables: Vegetables that have been previously cooked can be reheated using hot-holding equipment, making them convenient for additional servings or meal preparation.

- Sauces and gravies: These condiments can be safely reheated in hot holding equipment to ensure their smooth consistency and proper serving temperature.

Foods That Should Not Be Reheated Using Hot Holding Equipment

While certain foods can benefit from reheating using hot-holding equipment, there are others that should not be reheated in this manner due to safety and quality concerns.

These include:

- Reheating seafood: Seafood is highly sensitive to heat and can easily become overcooked or dry when reheated in hot holding equipment. To maintain its delicate texture and flavor, it is best to avoid reheating seafood using this method.

- Reheating fried foods: Fried foods, such as french fries or chicken nuggets, tend to lose their crispiness and become soggy when reheated in hot holding equipment. To enjoy their original texture, consider using alternative reheating methods like an oven or stovetop.

- Reheating delicate desserts: Delicate desserts like pastries, cakes, or custards can lose their texture and become mushy when reheated in hot holding equipment. It is best to consume these desserts fresh or use alternative reheating methods that preserve their quality.

- Reheating dairy-based dishes: Dishes with dairy products, like cream-based soups or creamy pasta sauces, can separate or curdle when reheated in hot holding equipment. To avoid compromising their smoothness and consistency, use other reheating methods like a stovetop or microwave.

Remember, not all foods are suitable for reheating using hot-holding equipment. Make sure to select the appropriate method to maintain the quality and safety of your meals.

Equipment Selection And Maintenance

Hot holding equipment is not recommended for reheating food as it may not reach the required temperature to kill bacteria and ensure food safety. It is important to select the appropriate equipment and properly maintain it to prevent foodborne illnesses.

Choosing The Right Equipment For Your Needs

When it comes to reheating food using hot-holding equipment, selecting the appropriate equipment is crucial.

Here are some factors to consider when choosing the right equipment for your needs:

- Size and capacity: Determine the amount of food you need to reheat regularly. Choose equipment that can accommodate your desired quantity without crowding or overloading.

- Temperature control: Look for equipment that offers precise temperature control. This will allow you to maintain the required heat levels for safe reheating.

- Versatility: Consider the types of food you usually reheat. Some equipment may be more suitable for specific dishes, such as steam tables for soups and sauces or convection ovens for baked goods.

- Energy efficiency: Opt for equipment that is energy-efficient to minimize operational costs and reduce your environmental impact.

- Durability: Invest in equipment that is built to last. Sturdy and well-maintained equipment will save you money in the long run.

Proper Cleaning And Maintenance Practices

To ensure the safety and effectiveness of your hot-holding equipment, it is essential to follow proper cleaning and maintenance practices.

Here are some guidelines to keep in mind:

- Regular cleaning: Clean your equipment thoroughly after each use. This includes removing any food remnants and sanitizing surfaces to prevent bacterial growth.

- Follow manufacturer’s instructions: Refer to the equipment’s manual for specific cleaning instructions. Manufacturers often provide guidelines on the appropriate cleaning agents and techniques for their products.

- Check for wear and tear: Conduct routine inspections to identify any signs of damage or malfunction. Replace worn-out components promptly and repair any defects to prevent further deterioration.

- Calibration and temperature checks: Regularly calibrate your equipment to ensure accurate temperature readings. Use a food thermometer to verify that the internal temperature is within the safe range for reheating.

- Train staff properly: Educate your staff on proper cleaning procedures and maintenance protocols. Regular training will help maintain consistency and ensure that the equipment is handled correctly.

By choosing the right equipment and implementing proper cleaning and maintenance practices, you can safely and efficiently reheat food using hot-holding equipment.

Risk Of Bacterial Growth

Hot-holding equipment may not be the best choice for reheating food, as it can increase the risk of bacterial growth. This can compromise food safety and lead to potential health issues if consumed. It is important to consider alternative methods of reheating that ensure food is heated thoroughly and evenly.

Hot-holding equipment is often used in commercial kitchens and food establishments to reheat and keep food warm. While it can be convenient and efficient, there are certain risks associated with its use, particularly the risk of bacterial growth. Understanding the conditions that can lead to bacterial growth and implementing best practices to mitigate this risk is crucial for maintaining food safety.

Conditions That Can Lead To Bacterial Growth:

- Improper temperature control: If the hot holding equipment does not maintain the proper temperature, it can create an ideal environment for bacteria to thrive. Temperatures between 40°F (4°C) and 140°F (60°C) are considered the danger zone, as bacteria can multiply rapidly within this range.

- Extended time period: Keeping food in hot holding equipment for an extended period can increase the risk of bacterial growth. Bacteria need time to multiply, and the longer food remains in the danger zone, the higher the chances of contamination.

- Inadequate cleaning and sanitization: Failure to regularly clean and sanitize hot holding equipment can lead to the buildup of bacteria and other pathogens. This can compromise the safety of the reheated food and increase the risk of foodborne illnesses.

Best Practices To Mitigate This Risk:

- Monitoring temperatures: Regularly check the temperature of the hot holding equipment using a food thermometer to ensure it is within the safe range. Make sure to calibrate the thermometer regularly for accurate readings.

- Time control: Limit the time that food is spent in hot holding equipment. It is recommended to discard any food that has been held for more than two hours within the danger zone to minimize the risk of bacterial growth.

- Proper cleaning and sanitization: Establish a regular cleaning and sanitization schedule for hot holding equipment. Follow manufacturer guidelines for cleaning agents and techniques to ensure effective removal of bacteria and other contaminants.

- Training and education: Provide proper training to staff members who operate and maintain the hot holding equipment. Educate them about food safety practices, including temperature control, time limits, and cleanliness.

- Regular maintenance: Schedule regular maintenance for hot-holding equipment to ensure proper functioning and accurate temperature control. Inspect for any signs of wear and tear, and promptly repair or replace any faulty equipment.

Implementing these best practices can greatly reduce the risk of bacterial growth associated with using hot-holding equipment for reheating food. By prioritizing food safety and following guidelines, you can maintain the quality and integrity of your meals, safeguarding the health of your customers.

Remember, food safety is a shared responsibility, and being proactive in preventing bacterial growth is essential in the food service industry.

Impact On Food Quality

Hot-holding equipment can impact the quality of reheated food. Careful consideration should be given to its use, as it can affect taste, texture, and nutritional value. Proponents argue for its convenience, but it’s important to weigh the potential drawbacks as well.

Hot-holding equipment is a popular choice for reheating food in many commercial kitchens. However, it’s important to consider the potential impact on food quality before deciding whether to use this method. When food is reheated using hot holding equipment, there can be changes in both texture and flavor, which may not always be desirable.

This article explores the effects on food quality and strategies to minimize any negative impacts.

Texture And Flavor Changes When Using Hot Holding Equipment:

- Texture changes: Reheating food in hot holding equipment can lead to changes in texture. Foods that were previously crispy or crunchy may become softer and lose their desired texture. This is especially true for fried items like french fries or breaded chicken. The prolonged exposure to heat can make them soggy and less appetizing.

- Flavor changes: Another consideration when using hot holding equipment is the impact on flavor. Some foods may lose their original taste or develop an off-flavor when reheated this way. For example, delicate herbs or spices may lose their freshness, resulting in a less flavorful dish. Additionally, over time, the flavors in composite dishes may become muddled, as the heat can mix and blend the ingredients.

Strategies To Minimize Negative Effects:

- Use proper packaging: Selecting the right packaging for your hot-holding equipment can help maintain the desired texture and flavor of reheated food. Opt for materials that provide some airflow, allowing moisture to escape and preventing condensation buildup, which can contribute to sogginess.

- Monitor temperature and time: Keeping a close eye on both temperature and time is crucial to minimize the negative effects of reheating. Ensuring that the hot holding equipment maintains the proper temperature, typically above 140°F (60°C), will help retain the desired texture and flavor. Additionally, adhering to recommended holding times can prevent overcooking and subsequent quality degradation.

- Consider pre-portioning: Pre-portioning food before reheating can help maintain its quality. By reheating only what is needed at a given time, you can minimize the exposure of the entire batch to prolonged heat and potential quality decline. This approach is especially useful for dishes that are sensitive to texture, such as fried or crispy items.

- Implement rotation practices: To further minimize the negative effects of reheating, implement rotation practices in your kitchen. By using the first in, first out (FIFO) method, you can ensure that food is reheated and served in a timely manner, minimizing the time spent in hot holding equipment and preserving its quality.

- Consider alternative reheating methods: Depending on the type of food, alternative reheating methods may be worth exploring. Using methods such as stovetop reheating, oven reheating, or microwave reheating can provide more control over the temperature and time, minimizing the impact on texture and flavor.

Remember, while hot holding equipment provides convenience in reheating food, it’s essential to be aware of its potential impact on food quality. By considering the texture and flavor changes that can occur and implementing strategies to minimize negative effects, you can ensure that reheated food maintains its desired characteristics.

Other Reheating Methods To Consider

Consider alternative reheating methods such as using hot holding equipment to retain food temperature. This helps to avoid common overused reheating techniques and ensure the food is heated evenly and safely.

When it comes to reheating food, hot-holding equipment is not the only option available. Depending on your specific needs and circumstances, there are other methods you can consider.

Here are a few alternatives to hot holding equipment and the pros and cons of each:

Oven Or Stove

Heating food using an oven or stove is a common method for reheating leftovers.

Pros:

- Allows for even heating and can retain the texture and flavor of the food.

- Suitable for larger portions or dishes that require oven-like conditions.

Cons:

- Takes longer to heat compared to other methods.

- Requires monitoring to prevent overcooking or drying out of the food.

Microwave

The microwave is a fast and convenient way to reheat food, especially for single servings.

Pros:

- Quick heating time, usually within a few minutes.

- Ideal for smaller portions or reheating beverages.

Cons:

- Uneven heating can result in hot and cold spots within the food.

- This can lead to a loss of texture and crispness in some foods.

Steamer

Using a steamer is a gentle method that helps retain moisture and prevents drying out of the food.

Pros:

- Provides a moist heat environment for reheating, maintaining the food’s original texture and flavors.

- Suitable for delicate foods like vegetables, fish, and dumplings.

Cons:

- Takes longer to reheat compared to other methods.

- May not be ideal for larger portions or dense foods that require direct heat.

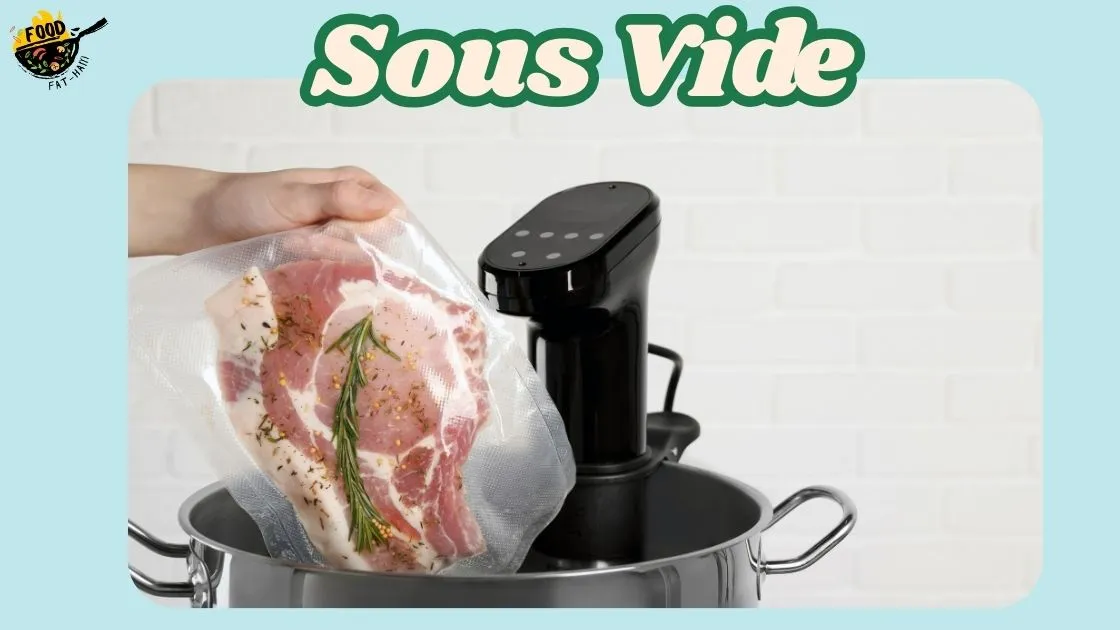

Sous Vide

Sous vide cooking involves sealing the food in a vacuum bag and immersing it in a precisely controlled water bath.

Pros:

- Ensures consistent heating throughout the food with minimal risk of overcooking.

- Ideal for more delicate foods and items that require precise temperature control.

Cons:

- Requires specialized equipment and setup, which can be costly.

- Not suitable for every type of food or convenient for quick reheating.

Choosing the right reheating method depends on the nature of the food you are reheating and your specific requirements. While hot-holding equipment may be a popular option, alternatives such as ovens, microwaves, steamers, and sous vide can provide viable alternatives with their own set of advantages and limitations.

Consider the pros and cons of each method to determine the most suitable option for your needs.

Frequently Asked Questions On Should You Use Hot Holding Equipment To Reheat Food

Can You Use A Hot Holding Unit To Reheat Food?

Yes, you can use a hot-holding unit to reheat food safely and efficiently.

Why Should You Use Hot Holding Equipment To Reheat Food?

Hot-holding equipment should be used to reheat food because it helps maintain safe temperatures, ensures even heating, prevents bacterial growth, and keeps the food fresh.

Should Never Use Hot Holding Equipment To Reheat Food Unless It’s Designed For It?

Never use hot holding equipment to reheat food unless it’s specifically designed for that purpose.

What Equipment Should You Use To Reheat Food?

To reheat food effectively, use the microwave, oven, stovetop, or toaster oven equipment.

Conclusion

Using hot holding equipment to reheat food can be an effective and efficient method for many food establishments. It ensures that food is kept at safe temperatures, minimizing the risk of bacterial growth. This is especially crucial in busy kitchens, where reheating food quickly is necessary to meet customer demand.

Hot holding equipment also allows for better control over the reheating process, preventing overcooking or drying out of the food. However, it is important to note that not all types of food are suitable for reheating using hot-holding equipment.

Delicate dishes, such as soufflés or pastries, may not retain their original texture and quality when reheated this way. It is also crucial to follow proper food safety guidelines and consistently monitor the temperatures of the hot holding equipment to prevent foodborne illnesses.

Ultimately, the decision to use hot holding equipment to reheat food depends on the specific circumstances and the type of food being reheated. It is important to consider factors such as food safety, efficiency, and the desired outcome when making this decision.

By carefully weighing these factors, food establishments can make informed choices that ensure the delivery of safe and delicious meals to their customers.